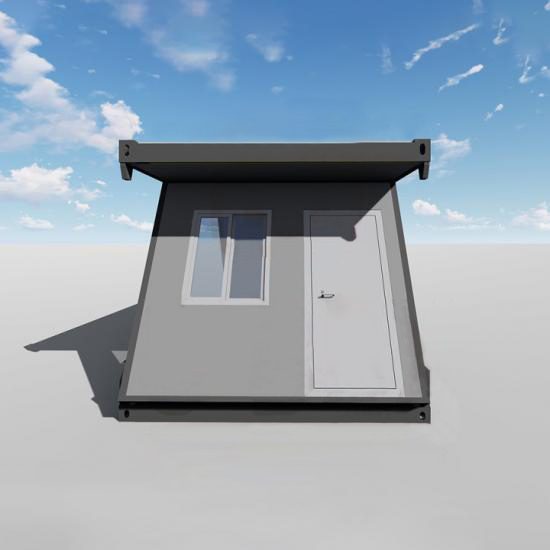

The commercial real estate landscape is evolving at breakneck speed. Consumers crave one-of-a-kind experiences, and businesses need spaces that can pivot with market demands. Traditional brick-and-mortar buildings are too slow to build and too rigid to adapt. Even shipping container houses—once hailed as a flexible solution—come with logistical headaches and steep costs. Enter the Foldable Container House: a breakthrough that marries engineering smarts with real-world practicality, redefining how businesses approach space.

The Genius of Foldable Design: Solving Old Problems

At its core, the Foldable Container House fixes a critical flaw in traditional shipping containers: their inability to shrink for transport or storage. A standard 20–40-foot shipping container stays its full size even when empty, wasting space and driving up costs. The Foldable Container House changes the game with a collapsible steel frame featuring precision hinges and heavy-duty latches. When folded, the unit compresses to just one-third of its expanded size—making it far easier to move and store.

Materials matter too. The exterior uses corrugated galvanized steel (or weather-resistant corten steel) for durability, while the interior relies on lightweight aluminum framing and insulated panels. These choices cut down on weight without sacrificing strength. And unlike flimsy pop-up structures, foldable units meet global building codes—withstanding 150 mph winds and 30 psf snow loads when expanded.

Transportation & Logistics: Saving Time and Money

For businesses with multiple locations or seasonal needs, moving and storing space is make-or-break. The Foldable Container House delivers two game-changing advantages:

-

Transport Efficiency: A single truck can carry 3 folded 40-foot units—vs. just 1 traditional container. For a coffee chain opening 10 stores, this cuts transport costs by 60%. International shipping? Folded units take up 40–50% less space in cargo containers, slashing ocean freight bills.

-

Storage Flexibility: In off-seasons (like a beach restaurant in winter), folded units fit in a standard warehouse—using 70% less space than traditional containers. No need for pricey storage yards. And if you’re opening a pop-up in a remote spot (e.g., a mountain music festival), the compact size fits on flatbed trucks—no cranes required.

Sustainability: Good for Business, Great for the Planet

Today’s consumers vote with their wallets—prioritizing brands that care about the environment. The Foldable Container House checks every green box:

-

Recycled Materials: Most units use steel from old shipping containers or industrial scrap. When a unit reaches the end of its life, 95% of its parts can be recycled—keeping tons of waste out of landfills.

-

Energy Savings: Insulated panels (with R-values up to 12) and double-glazed windows cut heating/cooling costs by 30–40%. Some models even add solar panels for off-grid power, perfect for remote coffee shops or festival stalls.

-

Circular Economy: Unlike buildings that get torn down, foldable units can be reused indefinitely. A single unit might start as a Tokyo coffee shop, relocate to a Berlin art fair, then become a community library in Nairobi. Less waste, more value.

Real-World Wins: Businesses Thriving with Foldable Units

Across the globe, companies are using Foldable Container Houses to build flexible, profitable spaces. Here’s how:

Case 1: “Brew & Go” Coffee Kiosks (Europe)

A European coffee brand wanted to dominate city streets without the cost of brick-and-mortar stores. They chose Foldable Container Houses for their kiosks—featuring floor-to-ceiling glass, built-in espresso machines, and bright orange branding (matching their logo). The foldable design let them test 10 locations in 6 months (vs. 12+ months for traditional builds). By year’s end, each kiosk generated twice as much revenue as their smallest store.

A European coffee brand wanted to dominate city streets without the cost of brick-and-mortar stores. They chose Foldable Container Houses for their kiosks—featuring floor-to-ceiling glass, built-in espresso machines, and bright orange branding (matching their logo). The foldable design let them test 10 locations in 6 months (vs. 12+ months for traditional builds). By year’s end, each kiosk generated twice as much revenue as their smallest store.

Case 2: “Beach Bites” Seasonal Restaurant (Australia)

An Australian restaurateur wanted to cash in on summer tourism at a popular beach. Traditional construction would’ve taken 6 months and $200,000. Instead, they used a Foldable Container House: installed in 2 days, cost $80,000, and earned $150,000 in 3 months. When winter hit, they collapsed the unit and stored it—ready to relaunch the next summer.

An Australian restaurateur wanted to cash in on summer tourism at a popular beach. Traditional construction would’ve taken 6 months and $200,000. Instead, they used a Foldable Container House: installed in 2 days, cost $80,000, and earned $150,000 in 3 months. When winter hit, they collapsed the unit and stored it—ready to relaunch the next summer.

Case 3: “Pop-Up Retail” for Luxury Fashion (Europe)

A high-end fashion brand needed a flexible space for Fashion Week pop-ups. Foldable Container Houses delivered: customized with LED lighting, rotating clothing racks, and digital screens. The units were assembled in 1 day, disassembled in 4 hours, and reused for 5 events across Paris, Milan, and Berlin. The brand reported a 30% jump in customer engagement vs. traditional pop-up tents.

A high-end fashion brand needed a flexible space for Fashion Week pop-ups. Foldable Container Houses delivered: customized with LED lighting, rotating clothing racks, and digital screens. The units were assembled in 1 day, disassembled in 4 hours, and reused for 5 events across Paris, Milan, and Berlin. The brand reported a 30% jump in customer engagement vs. traditional pop-up tents.

What’s Next? Innovations on the Horizon

The Foldable Container House market is booming—projected to grow at 6.8% annually through 2032 (per Grand View Research). Here’s what’s coming:

-

Smart Tech Upgrades: Future units may include IoT sensors (to monitor temperature, humidity, and foot traffic), app-controlled folding mechanisms, and AI-powered energy systems. Imagine adjusting your coffee shop’s AC from your phone or getting real-time sales data from built-in sensors.

-

Modular Expansion: Brands will soon connect multiple foldable units (side-by-side or stacked) to create larger spaces. Think: a 2-unit coffee shop with indoor seating and an outdoor patio, or a 3-unit restaurant with a kitchen, dining area, and bar. Start small, grow as you go.

-

Eco-Friendly Materials: Expect bio-based insulation (like hempcrete) and green roofs with rainwater harvesting systems. These upgrades will help businesses earn LEED or BREEAM certification—boosting their eco-cred and attracting conscious consumers.

Conclusion: The Future of Space is Foldable

The Foldable Container House isn’t just a product—it’s a solution to modern business pain points. It slashes costs (by up to 50% vs. traditional containers), simplifies logistics, and offers unmatched flexibility. For first-time entrepreneurs, it’s a low-risk way to test ideas. For established brands, it’s a fast track to new markets. For the planet, it’s a sustainable alternative to wasteful construction.

As the world becomes more mobile and consumers crave unique experiences, the Foldable Container House will lead the charge. It’s not just a building—it’s a launchpad for innovation, a tool for growth, and proof that when engineering meets creativity, amazing things happen.

In a world where change is constant, the Foldable Container House is the ultimate flexible asset—ready to adapt, grow, and succeed alongside the businesses it houses.

EMAIL : info@hig-housing.com

EMAIL : info@hig-housing.com

IPv6 network supported

IPv6 network supported