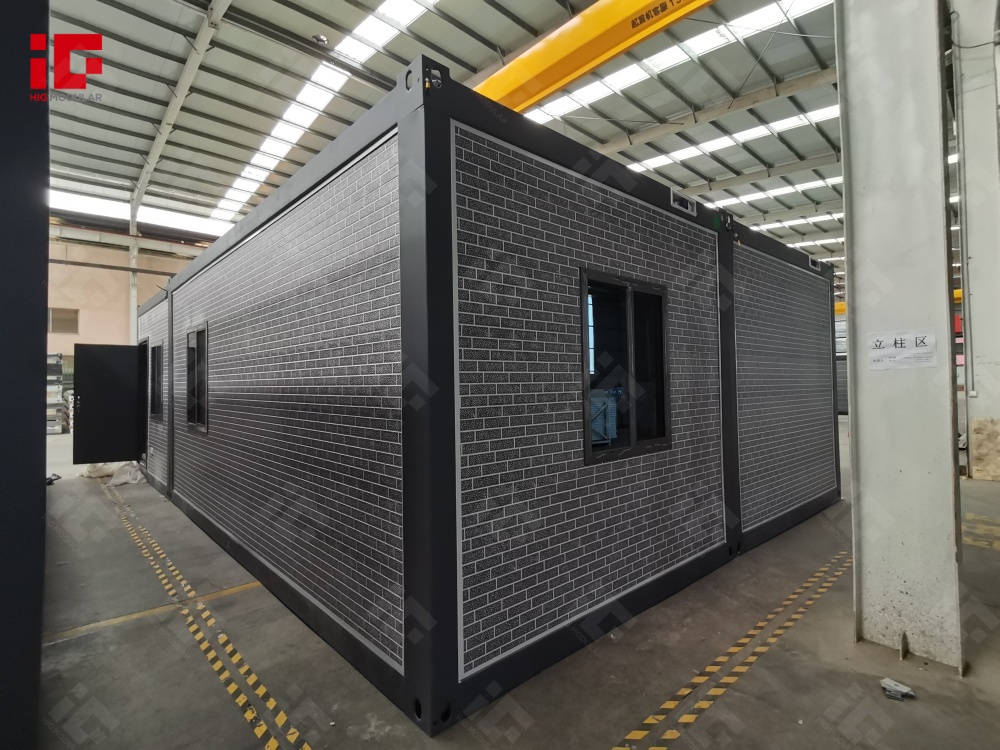

Professional integrated housing one-stop solution provider

including prefabricated container house, modular building and steel structure etc.

Projeto personalizado

Sanita móvel

Casa de contentor amovível

Casa pré-fabricada

Casa de contentor expansível

Casa de contentor marítimo

Edifício de estrutura de aço

Casa de contentores

The modular construction industry is undergoing a paradigm shift, driven by the demand for aesthetic personalization and operational efficiency. Detachable container houses, long lauded for their structural resilience and sustainability, now gain prominence for mimicking traditional architectural styles—especially the realistic brick – like exterior in recent models. This fusion of classic aesthetics and modern modularity is more than a trend; it proves the industry’s adaptability.

The brick – textured exterior of detachable container houses stems from advanced material science and precise engineering. Manufacturers follow these steps:

This process isn’t limited to bricks. Wood grains, stone textures, and custom artwork can be applied similarly, offering endless design possibilities. The result is a modular structure that fits any architectural context, from historic districts to modern cities.

While the exterior draws attention, the structural integrity of detachable container houses is fundamental. Here are key engineering specifications:

| Parameter | Detail | Impact |

| Frame Material | Galvanized steel (2.3mm thickness) | Resists corrosion and ensures rigidity |

| Sandwich Panels | 50mm rock – wool core (80kg/m³ density) | Provides thermal insulation and Class A fire safety |

| Assembly System | Custom galvanized connectors | Allows quick disassembly and relocation |

| Exterior Dimensions | 6000×3000×2840mm | Enables efficient transport and stacking |

| Interior Dimensions | 5800×2800×2500mm | Optimizes space for living and working |

| Resistência ao vento | 0.6KN/㎡ | Ensures stability in extreme weather |

| Seismic Resistance | Level 8 | Protects against earthquakes |

The galvanized steel frame—comprising beams, columns, and reinforced corners—provides a solid foundation. Rock – wool – core sandwich panels offer both thermal insulation and high fire resistance. This combination ensures the houses are not only visually appealing but also safe and comfortable for long – term use.

Detachable container houses offer significant economic and time advantages over traditional construction:

The customization and performance of detachable container houses drive their adoption across industries:

Sustainability is central to detachable container house design, covering three key areas:

The evolution of detachable container houses continues. Future advancements will likely focus on:

Detachable container houses are now a cornerstone of modern construction, where customization meets engineering excellence. Mimicking brickwork and offering endless design options challenges the perception of modular builds as purely functional. Backed by robust structure, economic benefits, and sustainability, these houses redefine architectural possibilities—creating adaptable, efficient, and visually striking spaces. As innovation progresses, they will shape built environments worldwide.

Digitalizar para o messenger :